News

25 Jun 2020

RØDE Claims Wireless – Burning Ambition Ignites

Subscribe to CX E-News

HISTORY: RØDE CEO Peter Freedman profiled in CX MAGAZINE May 2015

[May 2015] In January RØDE unveiled their new RØDELink digital wireless range at a dealer function in a beachside resort in San Diego. The dealers went nuts; standing, cheering and stomping. It was a moment, a room packed full of true believers from around the world.

“I’ve been trying to do wireless for 25 years. I started a project 16 years ago and stopped when I realised I didn’t have the money,” RØDE CEO Peter Freedman [pictured] said. “It was a dream. I kicked this off three years ago. The world has changed with the TV channels taking over the available bandwidth.”

RØDELink operates in the 2.4-gigahertz environment, and offers up to 100-metre range. RØDE says it offers the best signal-to-noise and longest range of anything in its class.

It has a massive head start; a decade ago RØDE started in the video microphone category with the advent of cheaper, mass-market digital video cameras.

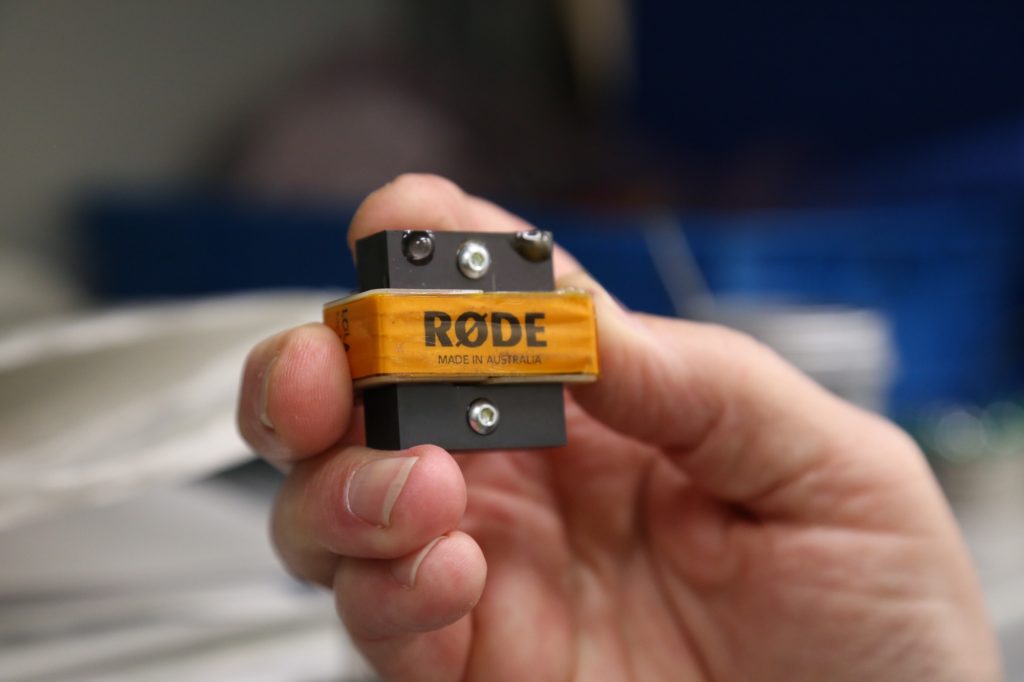

“I know I am known as an arrogant bastard”, Peter Freedman offers, “but this really is the best in its category; the volumes we are going to do will be amazing. We’re number one in video mics, I invented that category. There are hundreds of thousands sold each year now, and they will all plug into one of these” he says offering a RØDELink TX unit with a flourish.

“I have huge targets. The Free Trade Agreement with China and Korea is phenomenal; we opened our own office with a serious team just for marketing in China last year. We are opening in Korea and soon in India. We think globally, and act locally.”

MICRØPHONES FRØM SYDNEY

“I consider myself an enthusiastic amateur with all the high technology RØDE now owns. I like machinery, guns, cars. We could now make anything, but my heart lies in audio,” Peter says.

When Peter was young, the family emigrated from Sweden. His mum, Astrid, and dad Henry, set up Freedman Electronics in 1967. They had the exclusive rights to import the German brand Dynacord at that time.

‘Freedmans’ was the market leader in Sydney back then. They built and designed speakers, sold mics under the Freedman brand and installed literally hundreds of PA systems into the clubs around NSW.

Freedman Electronics was also the first retail PA shop in Australia, and was located in Ashfield.

After Henry died, Peter borrowed a lot of money to expand. This was at the wrong time, late 80’s, and with the wrong gear and the wrong people involved. It trashed his family business. “I lost everything, including the house”, he says.

“We had two little kids and it was six years of hell before we had any let up. It was really hard. I didn’t have a car, I walked to work. We had no money. The banks were on my back every day.

“I knew Colin Hill from years back when we met in the UK. He came to Sydney on a sales trip for another company. I offered him a job.

[See also Rode’s Colin Hill. Vale CX Network August 2013]

“I needed a salesman so I could concentrate on the technology and strategy. Colin moved over, and started working for me as my main sales guy. ‘Sand to the Arabs’ was Colin. The best in the business.

“Colin was out there selling sound systems to clubs, pubs and in one case he sold a system to a funeral parlour. He even sold them disco lights and a smoke machine for the chapel!”

Looking for anything else they could make a dollar from, Peter pulled out a Chinese studio mic sample he had bought in China way back in 1981.

“Colin took it out and showed some local dealers. He came back and said, ‘there’s a lot of interest in this’. It was the beginning of the new wave of home studios with the ADAT making good quality possible in small studios at low cost.

Everyone now wanted studio mics. We had a reasonable mic at less than a quarter of the price of anything around.

“We needed a name. After showing the mics around Colin said to me, ‘I think these will sell as fast as a rat runs up a drain pipe’. We both laughed and thought about calling them ‘Rat’ mics or ‘RØDENTS’. That’s where RØDE NT came from.

“I added the slash through the ‘O’ as well to make it look a bit European.”

“Things started okay, but they were selling very little in reality, and only in Australia, to a few dealers. Peter dreamt of the possibility of selling 500 mics a year. Last year they sold 600,000 mics.

“Things were still bleak, and our big break came with a last roll of the dice, a ticket to Los Angeles on the credit card, some flea infested motel rooms and a large bottle of Jack Daniels.”

“I walked around the NAMM tradeshow, literally asking everyone I met if they wanted to buy a mic. I was like some sleazy guy with watches running up his arms.

“After the show I went to the top studios doing demos to engineers at Capitol, A&M, Ocean Way, Westlake, Record Plant etc. They all gave me a few minutes, but none of them were interested. I used the names I met from these major studios as a way to get appointments at the next studio and then at the stores.”

I added the slash through the ‘O’ as well to make it look a bit European.

“About three weeks into my crusade, I went over to West LA Music. After six hours of tap dancing, they bought 100 mics. I teared up; I knew I must have something. We were off. We were just modifying the electronics in a Chinese mic, at that time too.

“As time went on, we sold more and more. A few years later, I could see my Chinese suppliers wanted a bigger slice of the pie. They were shocked at how many we were selling.

“I also started to realise that we could make better quality, and at a lower price with much lower lead times right here, if I had the equipment. That was when I decided to invest in manufacturing gear, and to make RØDE in Australia.

“Today we make microphones and other technology way better and cheaper than China. In fact we have better technology than any other microphone manufacturer in the world. You have seen some of this yourself today.”

HØW THEY DØ IT

We are inside Factory 2 at RØDE Microphones in Sydney. 150 staff make the entire RØDE range here, and, as we tour, the sprawling complex machinery is being moved into the newly purchased Factory 3.

RØDE has $26 million worth of machines and robotics, with more coming.

Raw ingredients enter the facility. Brass, copper, wires, plastics, paint and electronic components come in, and then completed microphones leave for all corners of the earth.

Aside from the finished product there is ‘swarf’ – all the metal milling and turning produces waste, which is recycled back to source.

“They pay me for it, and then they sell it back to me!” Peter says. “An example of our pursuit of the best possible technology in all areas can be seen in our main painting line.

“I wanted to offer black, non-reflective mic bodies. I needed a super hard paint that was just a few microns thick, so that it did not affect ultra fine threads.

“I found a military ceramic paint, and then bought the auto painting line to do it. After being assured it was not a problem it didn’t work. It cost me 600 grand to get it right and we had to rebuild it.

“I called Smith and Wesson, the gun makers – they have the only other auto spray line we could find – to see if they’d help me. They told me to bugger off!”

RØDE boss Peter Freedman is in an ebullient mood. “This is really cool. If you tell anyone I’m gonna kill you!”, he continues as we walk into the machining room.

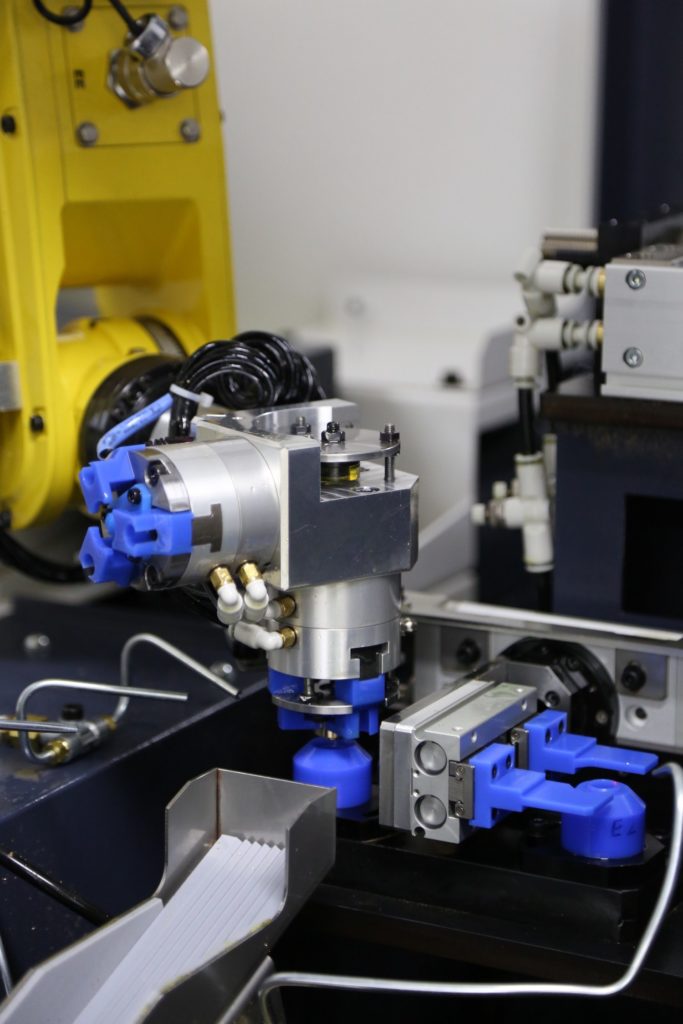

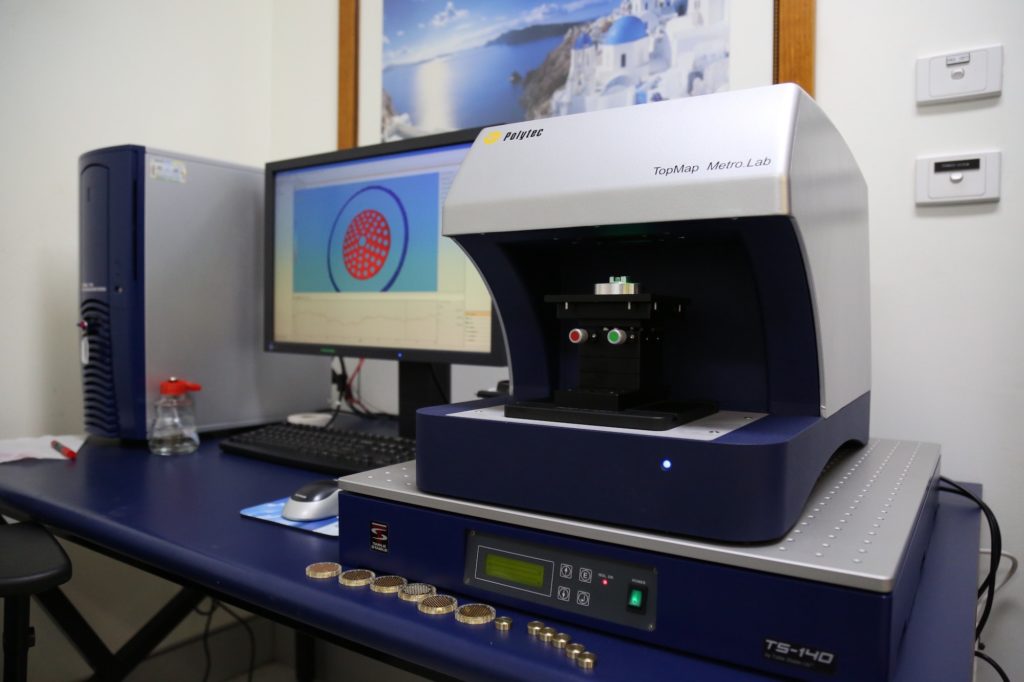

“This is spectacular, no other mic company in the world has one of these, nor the metrology to design parts this accurate. We are machining microphone backplates to a tolerance of less than a micron.

“Fully auto with a custom-machining cell operated by robotics. We start with a piece of brass, machine it flat, add micron features and then it produces the acoustic labyrinth of through holes and blind holes that make up a back plate in our transducers.

This is insane technology. It puts RØDE so far ahead of any other mic company in quality and consistency, and we developed it here and had it built in Japan by one of the world’s biggest CNC machine companies.

“This cell cost us over three million dollars, has taken well over three years and is unique. The manufacturer told us it was the most complex project they had ever worked on.”

I walked around the NAMM tradeshow, literally asking everyone I met if they wanted to buy a mic. I was like some sleazy guy with watches running up his arms.

“I’m still a wanker. I did luck it, there’s a lot of people in the Australian audio industry who are way more intelligent than I am. I found something hot at the right time, and I ran with it. I am not letting it go though.”

“I don’t need the money anymore. I am safe. If RØDE gets too big for me to manage, I will get out and maybe become a VC, or a ‘business angel’ –

“do a bit more mentoring and maybe help people with some dough. But I love audio; I’ve been working in audio for 40 years, and around it for 53 years, so I suppose I do know a little bit about this game now.”

“I don’t want to be arrogant, but the worst thing now for RØDE with the products we release is they may not sell as well as we predicted; we don’t lose money.

“There are also literally millions of people in the world who’ve bought a RØDE and that is an amazing feeling.”

HITS AND MISSES

“I am very competitive. That is obvious. Where does this come from? Maybe I need to prove something. Usually competitive people are insecure. That is probably true of me too.

“Of course, not everything I touch turns to gold, and stupidly I went and bought the studio monitor company Event a few years ago. Event was started by Russell Palmer, the CEO of Alesis, after he split from the owner, Keith Barr.

“They started with RØDE as the first product they sold and continued to be our importer in the US for quite a few years – they got us in. Without that lucky break, you could stand at a US trade show for ten years and everyone would just walk past.

“Eventually Event got into financial trouble, so I decided to buy the company. We set up an office and design lab in Seattle, and I spent six million on it in total. I always joke and say if I had of put six million dollars in a pile and lit it, at least there would have been some heat from it for me!

“Still, I learned a lot, and I do have the world’s best studio monitor to show for it. The sad thing is people don’t give a stuff! I had unbelievable problems sourcing components,and building them. Each one cost us money to sell.

“You don’t know what you don’t know. It is sad, I learned the hard way. Event is still going, and the Opal is still in production. I may still have another ‘play’ with the technology.

“With RØDE I predict that within five years, we’ll do more biz in China than the USA. Big call I know, but it’s going nuts for us right now.

“We now sell more studio mics in Germany than Neumann and Sennheiser, and that is something I am beyond proud of. They make great mics, but I am kicking their butts in so many categories. Business is war, and I like a good fight.

“We have worldwide distribution, and leading technology and equipment. We also have more than enough money to do anything we want. RØDE will be the biggest mic company in the world before I am done. Anyone who gets in my way will be cut down.”

Then we walk up some stairs, to experience the ‘El Dorado’ moment, the ultimate audio tool. Peter has just installed a full-sized anechoic chamber.

This oversized room is a non-reflective, non-echoing space where you can measure audio without atmospheric or architectural interference. There is a modern myth that if locked inside for a long duration, you start to go crazy as you hear your heart beating.

RØDE will be the biggest mic company in the world before I am done. Anyone who gets in my way will be cut down

So that’s RØDE 2015. As we go to press Factory 3 is being fitted out with more machines, and Factory 2 is being rearranged, with a machine or a tool for every occasion. We ride back to reception on one of Peter’s new golf carts that are now needed to get around the RØDE Campus – he has another being custom made in the US for his use that will have a petrol engine and a Ferrari front end!

CX Magazine – May 2015

LIGHTING | AUDIO | VIDEO | STAGING | INTEGRATION

Entertainment technology news and issues for Australia and New Zealand

– in print and free online www.cxnetwork.com.au

© VCS Creative Publishing

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.