RELIABLE

1 Mar 2023

Why spending more initially can cost you less in the long run…

Subscribe to CX E-News

In lighting, as with anything else, we have cheap gear, middling quality, and the primo stuff. A lot of you readers have been in this game long enough to tell the difference, and some of that experience has been earned quite painfully through poor experiences with cheaper gear.

It can be a bit harder to pick out the quality differences in pixel lighting. I should clarify that I’m not talking about pixel bars here; these are similar enough to LED bars that you probably already know what to look out for. What I’m referring to is lighting fixtures such as dots or pixel strips. They may not be your bread and butter, but may come up on a few jobs, so why not learn about them and add some more knowledge to your skillset?

When dealing with pixel strip lighting, you’re bombarded with different options. On the one hand you have really cheap options available through bulk online markets and auction sites. On the other hand, you have more costly options from established international suppliers like ENTTEC.

Putting them side by side you would almost be forgiven for thinking they are interchangeable … almost!

The width is about the same; they are both 12V, I can see a similar control chip on both, datasheets both report a similar output … so what is the difference here? Why wouldn’t I just go for the cheaper one and pocket the difference? Well, there are a number of things to seriously consider.

First off, the thickness of the copper strip it’s made from. This is not something that is apparent when simply comparing pictures and datasheets, but it is noticeable when you have the product in your hands in front of you. Cheap pixel strip is made using thin copper to keep costs down. Not only does this mean the strip is less robust, a thinner strip of copper is also less conductive, therefore voltage will drop off faster, meaning more power injections and more wiring for your project. So what you save in material cost you may well lose in additional power supplies and labour.

Next, while not a feature of the product itself, comes something you all know to be quite critical: support. One of the major reasons that many manufacturers manage to stay cheap is by not offering any product support.

So, if you run into trouble, you’re not going to have anyone to call up and ask why your tape is flickering, or why it’s not turning on at all. You won’t have someone to help you with specifying controllers or to walk you through how to configure yours. Saving a few bucks on a product becomes a false economy when you’re forced to spend hours learning, troubleshooting and installing all by yourself. Likewise, you’re not going to see much warranty support either.

Lastly, although there’s plenty more that we’re leaving out, is trust and reputation. Many segments of the lighting industry are regulated. Peak bodies like the IES put out standards that manufacturers must adhere to. If a decoder is compliant with DMX512, you can be sure that it will respond to a DMX signal from any DMX source you care to provide. However, things are a bit muggier with pixel lighting.

When controlling pixels, you want to make sure the protocol of your pixel strip is supported by your controller. This ‘protocol’ is essentially just a model of control chip released by a manufacturer. For example, the WS protocols come from WorldSemi. Since pixel lighting is not standardised, there is nothing stopping a manufacturer from creating a new variant of their chip, and then publishing it as the same ‘protocol’ as before. And when this is done, there is no way to distinguish between a 2018 version chip or a 2019 chip, since they’ll both say they’re WS_ _ _ _ or SK etc.

As you can guess, this can create all sorts of havoc, including LEDs flickering or otherwise not responding properly. If this is a hobby installation in your rumpus room, you might not care so much, but if this is part of a larger lighting rig in a theatre or studio where hundreds or even thousands of people might be watching, it becomes a lot more important.

So, this is when you turn to the premium pixel strip. Not only are you buying a better product, but you’re also buying reputation and peace of mind. You’re getting exactly what’s on the datasheet, and you have someone to talk to if you’re stuck.

What about with pixel dots?

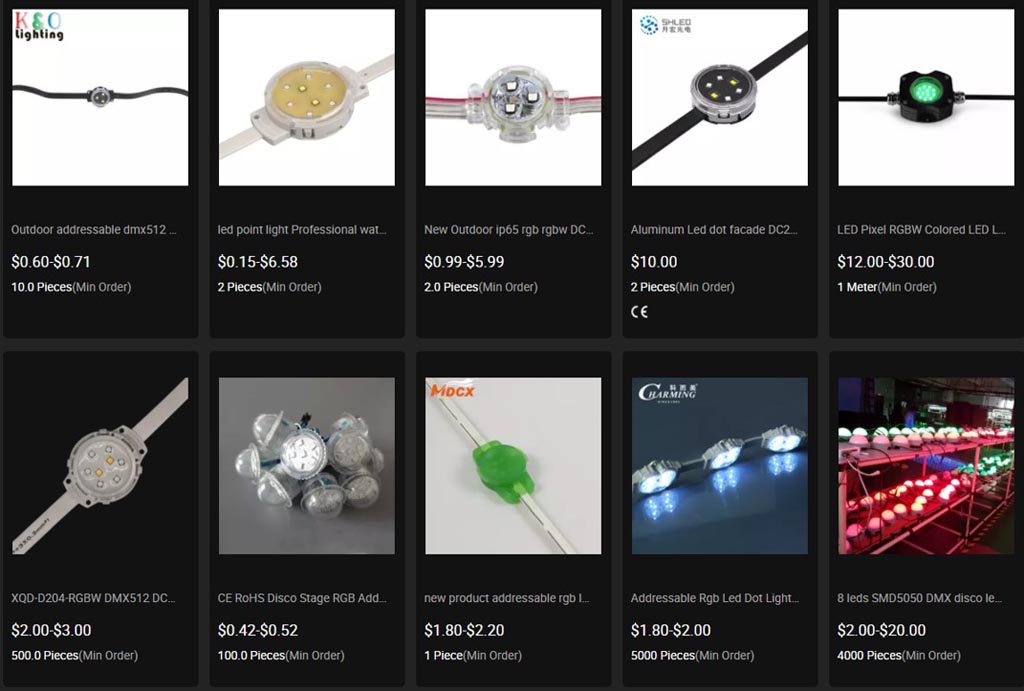

With pixel dots the quality difference can be even more drastic, though less visible. When looking into quoting up a pixel project involving dots, you’re again bombarded with options from bulk online sellers, and doing a simple search for “Pixel dots” can yield pages upon pages of results.

The prices seem remarkably low too; you’ll even find options listed for under $1 each! When you compare this against higher-end options which may be somewhere between $15-$20 each, it can be hard to justify choosing the more expensive option. However, there are a few things you should keep in mind.

Firstly, the price you see on the website is often a ploy to get you interested and open a dialogue with the manufacturer in question. In our own ‘experiment’ we saw that while the price on the website was $0.30, once you begin talking, you quickly find out that the website product is ‘discontinued’ or otherwise unavailable, so the actual quoted price came to $6.50 per dot, for a 24V dot with 6 RGB LEDs on it. Still not bad value, right? Well, when you consider that it’s $6.50 USD per dot, you start to see the price difference narrow dramatically.

“That’s fine!” you say. “Even after all this, it’s still half the price!”

Well, let’s get more scientific and compare the dot surfaces between a cheap, generic product and ENTTEC’s Australian designed and made SMART PXL series.

Both have the components covered with a clear epoxy or PU resin to ensure they are waterproof. At ENTTEC, we are aware that certain polymers can degrade over time. In fact, a lot of resins will yellow with UV exposure when they have the sun beating down on them. Discoloured resin will of course skew the colour of your dots’ light output. The ENTTEC dots, however, are made with a more expensive UV-resistant, optically clear polyurethane resin. This helps the product resist yellowing over time as well as keeping the resin somewhat flexible so it doesn’t go brittle and crack from repeated thermal cycling over the years.

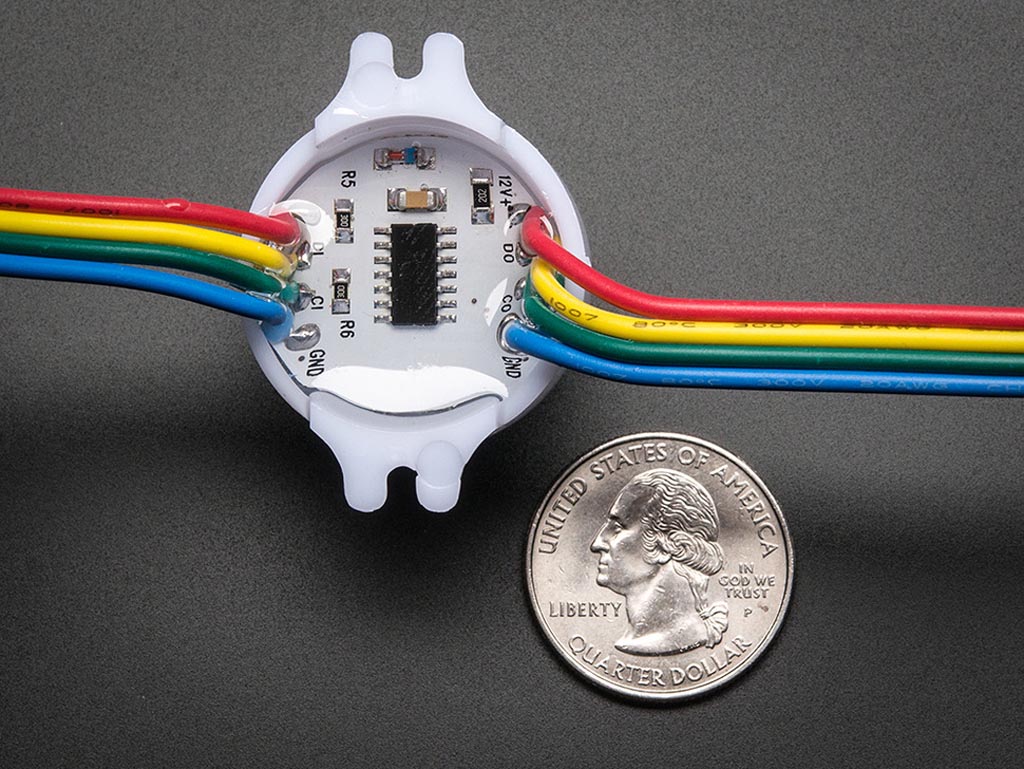

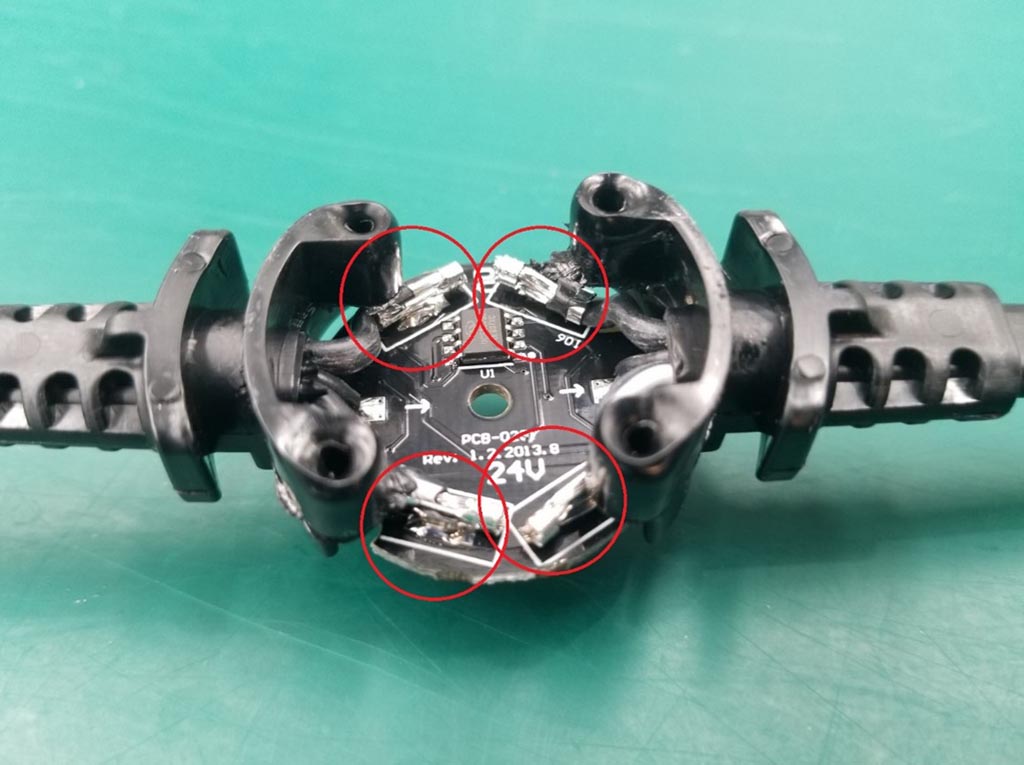

Let’s look at how these dots are constructed. This isn’t something you can generally see just by looking superficially at the dot but is something you can see once opening it up or dismantling it.

First let’s look at a cheaper option:

What we can see here is that the wires are simply soldered onto the PCB pads, and the whole assembly then encapsulated. If you’ve done much soldering at all you’ll know that even a good cable-pad solder joint is still relatively weak. Tension may not break the solder joint immediately but can easily pull the pad clean off the board. This is stabilised by the resin somewhat but is still a weaker joint that could more easily give way over time after temperature and load cycles.

Now let’s have a look at how the ENTTEC dot differs.

Power connections – VCC and ground aren’t simply soldered to a pad. Instead, the thick copper cable is crimped into a Molex crimp connector which has prongs that pierce through corresponding holes in the PCB. This makes for a sturdy mechanical connection even before solder is applied.

This is all then assembled into a robust outer case (made from either machined aluminium or UV-resistant injection-moulded PVC, depending upon the model in question), where the polymer over-mould fits snugly into a recess. Finally, the whole assembly is potted in UV-resistant, optically clear, PU resin. Strain on the cables whether it’s from handling during installation, or cyclic strain from wind, is borne by the over-mould, spreading that strain across the solid body. The PU resin helps to absorb some of that as well, and finally the electrical connections feature a strong physical connection to the PCB. All of this ensures that you get a product that stands up to harsh conditions and keeps operating solidly throughout years of continuous operation.

That’s a lot of engineering just for a pixel dot – so why is it necessary?

Well, in the long run, it makes more sense to opt for the primo product, because it means less maintenance. Yes, you could buy two sets of the cheaper dots for the same price, but then you also need to factor in the costs associated with maintenance/replacement. First, you have to partially or totally shut down the area, which could be difficult if it’s a popular public outdoor area. Then you have to factor in labour and time to replace the strings, not to mention any specialised equipment like cherry pickers to get up into difficult places.

Then of course there is the inconvenience and lost productivity – if you’re stuck maintaining a job, that’s one less opportunity you could be out on a new job.

Pixel lighting is growing in popularity and with that, we’re seeing more and more options appear using different types of gear. It can be a bit difficult to spot meaningful differences sometimes, but we hope this rundown can give you some tips on what to look out for.

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.