News

11 Aug 2020

Altronics and Redback – W.A. Made since ‘76

Subscribe to CX E-News

I talked to Altronic’s General Manager Brian Sorensen about being proudly Australian, the advantages of local manufacture, and how they’ve kept their customers happy for 44 years and counting…

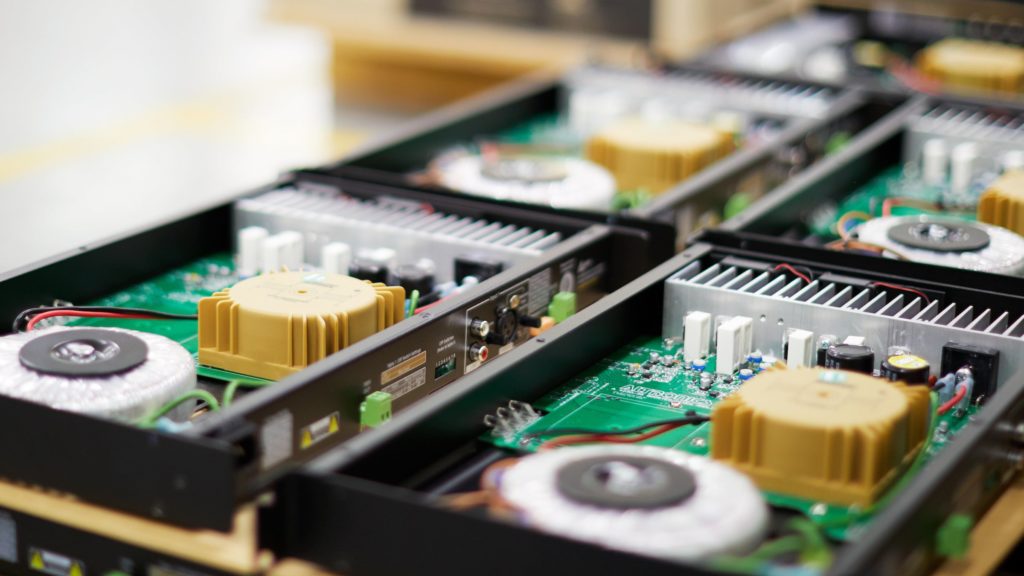

Redback commercial audio gear – stick your nose in the BOH rack at your local supermarket, gym, school, or Town Hall, and there it is. It’s Australia’s most ubiquitous range of amps, mixers, utility speakers, paging systems, and more.

Sitting squarely in the ‘affordable and reliable’ category, many audio pros assume it’s been made in China or India for years now. But no – it’s still all proudly designed and built in Perth.

OK Brian, I’ll ‘fess up. I was under the impression that some Redback was made elsewhere.

A lot of professional audio people don’t know we are still manufacturing here in Perth! Our Redback public address amplifiers, mixers, and more, are all designed and manufactured in Perth, and we have no intentions of moving away from that!

I think I got that idea because other well-known brands have moved offshore. Why did you decide to stay in Perth?

If we were to move our manufacturing overseas, all the expertise we’ve taken years to accumulate would be gone. All of the smart people we employ would move on to work elsewhere, and all of that knowledge would be gone for good. People like Steve May, our Head of Production, and Darian Lovett our R&D engineer.

Darian, for example, is self-taught, and phenomenal with audio equipment and microprocessor-based products. Both Steve and Darian have been with us more than 25 years. They do everything from designing printed circuit boards, to metalwork, and drawing panel layouts.

Another factor is that we’ve never seen anything in the commercial audio field coming out of Asia that you could use in Australia without modification. A lot of that product has been made for the US or Europe, and it just doesn’t suit what our market wants and needs.

If you’re manufacturing offshore, you’re also teaching a factory to make a product suitable for Australia that they could well sell to others, and end up competing against you.

What’s an example of a product you make that’s specifically for Australian standards and conditions?

The One Shot fire ceiling speakers for EWIS are a great example, and a range we keep expanding upon due to their success. The Australian standard AS ISO 7240.24(2015) that governs speakers for EWIS was updated in 2015, with a phasing-in period.

We designed the product, spending more than $250K in new plastic injection mould tooling to meet the standard, and shouldered the cost of all the testing and approvals from CSIRO to attain certification.

The One Shot fire ceiling speakers were put through an onerous testing regime subjecting the speakers to heat, cold, rain, vibration, impact, even sulphuric acid for 21 days. They were also measured for frequency response and SPL to check that they actually do what the manufacturer says they do. Since being certified thousands have been installed in projects all across Australia.

The ubiquity of Redback installations suggests to me there’s a lot of loyalty to the brand. How have you built that?

Well, I think it’s because we listen to the industry, and have a lot of expertise and experience. We take our customers feedback on-board and apply it directly to the products where we can. We try and focus on what our contractor and integrator customers actually want. When we’re designing a product, we keep the contractor in mind, focussing on ease-of-use and quick configuration on-site.

If you’re manufacturing offshore, you’re also teaching a factory to make a product suitable for Australia that they could well sell to others, and end up competing against you

The product needs to be easy to use for the end-user too. We also back our product with a ten year warranty, and in the rare case something does go wrong, we usually fix things while people wait with a cup of coffee at the repair centre.

Product development is a two-way street. What you think the market wants and what they actually want can diverge.

Oh yes. The way we see a product being used and how it’s actually used in the field can occasionally be quite different. People tend to find new ways of using a product that you wouldn’t necessarily have thought of. Every contractor does things in a slightly different way, which keeps things interesting.

For example, one of the products we supply is a 16-zone paging system, usually used in schools. One of our customers in NSW had a requirement to make a modification to enable ‘all-call’ for a different application. He sent the details of the mod to us, and we’ve implemented it in an updated version.

That’s how a lot of our products evolve. We have an idea of what a product should do, then we get feedback, and we include those ideas.

How have you kept up such a blanket coverage of the Australian market?

Our sales network has certainly grown over the years. We mostly rely on contractors to sell the product in. We know most of them buy Redback because of reliability, ease of use, and feature sets. We have a team of sales reps in each state that go knocking on doors, and often go to installs and help out where they can.

We still sell a lot of Redback – every new Aldi store in Australia, the chain of 7/11 service stations are all migrating to one of our products, Bunnings, Masters (when they were operating), BWS, Dan Murphy’s, Woolworths. It’s a workhorse product, all behind the scenes. It’s pretty basic, but it’s essential, so there’s a big market for it.

Does the ‘Australian Made’ label help or hinder you?

It’s a bit of both. Some love the idea, but others would do anything to save a dollar. ‘Australian Made’ can be warm and fuzzy, but the wallet talks in a lot of cases. Pricing’s usually the biggest issue; we’re not the cheapest, but we are priced around the mark.

When you’re designing and building in Australia, your biggest costs are wages, super, and all forms of compliance. The biggest cost in any of our products is the labour. We take that into account when we design our products, aiming for minimal wiring and labour.

We print panels in-house, and sub-manufacture PCBs with a local company; we supply them a kit of parts, they come back loaded up, and get bolted into the chassis. Any wiring is on plug-and-sockets and is minimal. We’ve reduced labour as much as possible.

If you take the lid off some product out of South East Asia, there’s miles of wiring; you couldn’t compete if you had to do that amount of labour.

What other activities are Altronics involved in that’s onshore here in Australia?

Aside from Redback, we supply component parts to other manufacturers that make niche products for the Australian market. We supply manufacturers of fire alarm and EWIS systems, nurse call equipment, traffic light controllers, those solar-powered road signage carts you see on side of the highway, and gear for remote mine site surveillance.

The Australian manufacturing sector is healthy, wide, and varied, and like us, most people don’t know it’s even there!

CX Magazine – August 2020

LIGHTING | AUDIO | VIDEO | STAGING | INTEGRATION

Entertainment technology news and issues for Australia and New Zealand

– in print and free online www.cxnetwork.com.au

© VCS Creative Publishing

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.