News

30 Jan 2018

Efficiency is King – Or Should Be

Subscribe to CX E-News

Efficiency is King – Or Should Be

By Simon Byrne.

The production business is a great way to waste money if you let it. The temptation is to spend more time and money so as to improve what we do. They key however, is to be efficient with the resources that you have, so you can build and focus on what is important.

The in-house AV providers have had this worked out for a long time. Go into most hotel ballrooms nowadays and there will already be a basic installed PA system, moving lights, projectors and screens available for hire. By doing this, they’ve stripped out the bulk of their labour costs for most of their gigs. As a side benefit, they’ve made it harder for outside contractors to compete whilst still being able to charge premium rates. It is smart, profitable business.

In many production companies, labour is about 50-55% of the costs, but only 40% of the charge out, so real gains can be made by getting smart and systemising things wherever possible.

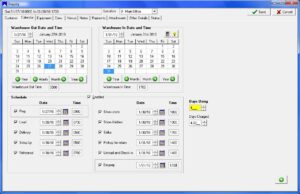

Starting with rental management software such as RentalPoint is really helpful, if not critical for efficiency in any production operation. Even for theatres who don’t charge out, in house AV, or the one man road warrior, it puts all the records in one place which delivers valuable information. On a day to day level, it forces you to be really structured, or at least think about your decisions when putting a gig together. It saves time and in my view, it is a critical planning tool which dramatically increases efficiency when it comes time to deliver the jobs.

Starting with rental management software such as RentalPoint is really helpful, if not critical for efficiency in any production operation. Even for theatres who don’t charge out, in house AV, or the one man road warrior, it puts all the records in one place which delivers valuable information. On a day to day level, it forces you to be really structured, or at least think about your decisions when putting a gig together. It saves time and in my view, it is a critical planning tool which dramatically increases efficiency when it comes time to deliver the jobs.

Also, in the long term, the data really pays off. For example, how much is that customer worth to me? She wants the job we did last year again, just duplicate it. Has that widget paid for itself? How many times has that piece of gear been out of service?

Long hours are part of what we do, so it makes sense to keep the key people fresh where possible. That means systems and processes that speed things up, or permit the substitution of people without compromising the end result will really shine.

Reducing the endless equipment prep and dismantle time is key. Equipment packaging is the obvious time saver both in the warehouse and on the gig. By investing a little more capital expenditure, regularly used configurations are packaged up which saves time every time it is deployed in the future. This is especially the case with networking. I can’t tell you how many gigs I’ve been on where crew have struggled to get gear to talk to each other. By having a very standardised methodology dramatic time savings will be made.

Standardised cables, looms and packages with colour code labels. I’d always try to buy the most reliable cabling possible because poor cabling costs money out on the jobs. Whether it be not enough cable, damaged connectors, poor performance, it all costs time and money out on the gig.

Standardised cable packages are a dramatic time saver in the warehouse because time is not spent picking, packing, unpacking and returning cables. Basically, have cable packages that will do 95% of the jobs and send them out on all jobs in road cases on wheels, ie; separate audio, power, lighting and vision cable packers. That may often mean more cables are brought than needed, but with the benefit of using the packers as dollies for other gear and being able to deal with unforeseen needs.

The business must be committed to keeping the standard packages intact, always. There is no point in standardising cable packs if they are going to be raided every other day, otherwise inefficiencies are introduced back into the system.

Dolly boards are cheap and make life easier too. If you haven’t got a lot on wheels, make it easier to move gear where it needs to be.

In my old company, the warehouse was laid out in a grid and row pattern. Row A, B, C and so on with clear signage. Then the bays had numbers as did the shelves. On RentalPoint, every piece of equipment had their location as part of the description. So a mixer might be “Yamaha LS9 B41”. The guys and gals pulling the equipment instantly know that the mixer is located in Row B, Bay 4, Shelf 1. The entire inventory and warehouse was done this way which meant casual staff unfamiliar with the operation, could still find gear quickly which frees up key personnel.

Absolutely everything has its place which meant we never had to hunt around for anything with the added benefit of immediately knowing if something was out or missing.

High end microphones were kept in steel cupboards with foam cutouts for every single one. Being a high theft risk item, we knew instantly if a microphone was unaccounted for.

I find checklists to be invaluable.

When I got my pilot’s licence, I learnt that in aviation, everything has a checklist and you are expected to use it, no matter how experienced you are. Even supremely experienced pilots are required to use a physical checklist despite knowing it off by heart. It really drove home to me that people are fallible and that by going through a simple check off process, you are forced to briefly think about all matters relating to the job at hand.

Equipment failure is normal so a process should be in place for this too. We carried bright red tags and if anything was faulty on a job, it got a tag, as did its case. Then when it got back to the warehouse, everyone could see there was an issue and have it sorted out straight away. Faulty equipment is not performing so it becomes dead money if it is not repaired. So it should be repaired quickly.

Monday is recovery day. That’s when everything is put away, paperwork done and maintenance carried out. In my production business, all the vehicles were filled and checked on Mondays and given a (very) quick clean. That way we knew they always had adequate fuel in them for the coming week’s work.

And talking of trucks and vans, either a ramp or tail lift means less manpower is needed when loading and unloading.

I’m not a fan of signage on vehicles. It’s advertising to criminals that it is probably worthwhile to break into. We never left loaded vehicles parked outside overnight for the same reason. I had 3 branded vehicles and all of them were broken into so I changed to unbranded. No break ins!

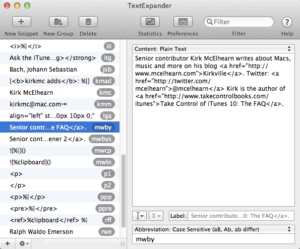

Use software to your advantage. Most gear manuals are available as PDF’s now so why not have the manual for every piece of equipment you use on your phone? I have an app on my Macbook called Text Expander. Text Expander saves my time by expanding custom keyboard shortcuts into frequently-used text and pictures. Rather than say typing my email address out, I have a 3 character code and Text Expander replaces the code with the full text.

Use software to your advantage. Most gear manuals are available as PDF’s now so why not have the manual for every piece of equipment you use on your phone? I have an app on my Macbook called Text Expander. Text Expander saves my time by expanding custom keyboard shortcuts into frequently-used text and pictures. Rather than say typing my email address out, I have a 3 character code and Text Expander replaces the code with the full text.

Another invaluable app is Lastpass which manages my 300+ passwords and other confidential information such as credit cards and autofills them when I’m online. For example, when I’m ordering from a Ecommerce site, Lastpass can autofill my credit card and address details which saves a lot of time. It all counts.

Evernote is a great favourite too. It is an app designed for note taking, organising, and archiving and it does it by creating “notes”. A “note” can be almost anything from text, files and photos. It’s real power lies within it’s optical character recognition and search engine so it is a fast way to store and find stuff. Anytime I need to keep a note of something, it goes into Evernote.

Whilst getting efficient saves money, it really frees up time to finesse your work. You have the gift of time to be better.

This article first appeared in the print edition of CX Magazine December 2017, pp.60-61. CX Magazine is Australia and New Zealand’s only publication dedicated to entertainment technology news and issues. Read all editions for free or search our archive www.cxnetwork.com.au

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.