News

3 Jul 2020

Luxibel’s UVC Sterilisation Fixtures

Subscribe to CX E-News

UV light has been used for sterilisation and disinfection since the mid-20th century. It has also been widely studied, with countless publications on the effectiveness of UVC for the sterilisation of air and surfaces. With advancements in technology, specifically in the UV bulbs themselves, UVC’s reliable lifespan in the thousands of hours and smaller size has broadened the field for where it can be used: water, air, fruits, vegetables, surgical utensils, and on electronic devices where liquid disinfectants would either be less effective or damage the items.

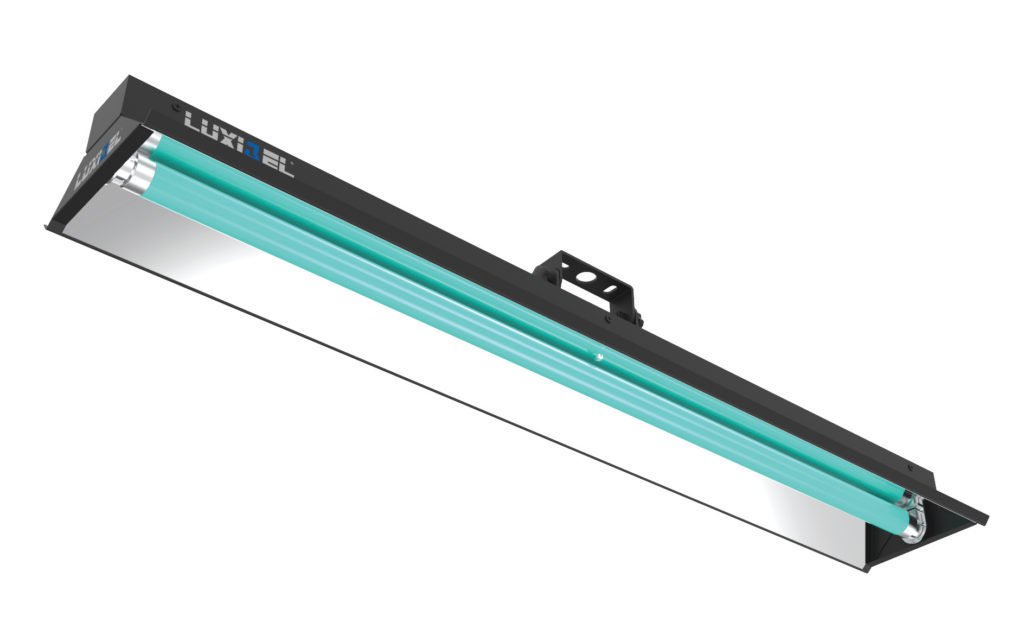

Luxibel UVC fixtures use Philips Germicidal Lamps; low-pressure tubular fluorescent ultraviolet (TUV). Extensive laboratory studies have been published on the effectiveness of the Philips Germicidal TUV lamps, gaining them approval for use in air, surface and water purification.

With a range of UVC fixtures from Luxibel on offer, and an obvious urgency in the market to keep everyone Covid-19 free, we asked Luxibel’s International Sales Manager Damon Crisp and Paul Rumble, General Manager for Victoria with Australian and New Zealand Luxibel distributor ULA Group, some hard questions about safety, validation, regulation, and deployment of these unique products.

Were Luxibel already considering manufacturing UVC fixtures before the COVID-19 pandemic?

Damon: Luxibel’s CEO Mr Glenn Roggerman is heavily involved with the medical community in Belgium, so much so he flies the emergency Helicopter Medic 1 to assist in serious life threatening situations. He was aware before Covid-19 that hospitals and medical centres the world over were suffering acutely from HAIs (Healthcare Associated Illnesses) and seeking a solution.

UVC had all ways been part of our plan to grow the Luxibel lighting division, but it’s fair to say this became a priority as the pandemic started to hit Europe. Something was required immediately to stop its onslaught, and to help the industry return to the road safely.

Which health/regulatory bodies have confirmed UVC’s effectiveness for disinfection?

Damon: The CDC (Centre for Disease Control and Prevention), FDA (U.S Food and Drug Administration), ICNIRP (International Commission on Non-Ionizing Radiation Protection), and the National Health Service UK have all confirmed UVC’s effectiveness.

It is also worth noting the warnings against so called “domestic/handheld” UVC sanitation fixtures that some companies are promoting. The Luxibel fixtures should not be mistaken for the units spoken about by the ARPANSA (Australian Radiation Protection And Nuclear Safety Agency) and CIE (International Commission on Illumination).

Which specific health or manufacturing standards do the fixtures meet?

Damon: They specifically meet ISO 15858:2016(en), and we have FDA approval pending.

Does the person or company installing products from the UVC range need any special training, qualifications, or licenses?

Paul: As the units are mains powered, they have to be installed by a certified electrician. Beyond that, the B Air, as an enclosed unit, works by fan-forced air passing by the germicidal lamps at a rate sufficient to ensure a maximum kill rate.

When designing an installation, the volumetric space to be treated needs to be calculated to determine the number of units required, as we do when specifying the correct haze machine for a project.

The B Direct units are treated as we would any luminaire, using software to plot their location within the 3D environment. Consideration is given to any objects that will cast shadows, sometimes requiring multiple fixtures to ensure a consistent and even coverage across surfaces.

The performance of surfaces within the space will also influence the coverage, so for areas with reflective materials, the ambient coverage will increase as it does with production lighting. Once we have the 3D model with sufficient coverage, we can calculate the time required to reach the desired kill rate.

The main influence on this is the distance the fixture is from the area to be treated. Just as it is in photography, the lower the light level the longer the exposure required.

How is an installation validated?

Paul: Once the system is installed the coverage and exposure time can be measured and focused for maximum effectiveness through the use of dosimeter stickers or cards. These very simple and cost-effective products consist of a photochromatic ink which is stimulated by the UVC light. An enclosed colour scale displays the dosage level it has been exposed to, much the same as a PH test kit does for liquids.

What special safety measures need to be adhered to during installation?

Damon: All UVC product should be fitted to a separate mains spur, which we advise should have MCB and RCD protection. Our partners must have fully calculated the cubic capacity of the room, and taken dosimeter readings so the client can be sure their purchase will do what we claim.

Only authorised professionals should undertake to evaluate the quantity and type of units required in specific rooms. We have a range of medical strips that can confirm kill rates on surfaces, along with special air meters that can read the purification process both before and after.

Testing of all safety features, including the 360 degree cut off sensor, audible alarm and red ‘Warning- In Operation’ LED, must be done to ensure the installation is safe to hand over to the end client.

Paul: These are electrical devices that need to be terminated by a competent person holding the correct qualifications as set out in the Australian Standards. Also, PPE such as gloves and eye protection should be worn when handling lamps of any type, including the low-pressure tubes used in the Luxibel UVC range.

What safety measures need to be taken when the unit is in use?

Damon: The B-Air Kills up to 99.9% of all airborne bacteria and is totally safe to operate when human beings or animals are in the room due to its enclosed housing. Direct kill units used for decontamination and disinfection of surfaces like the B-Direct units can only be operated when no humans or animals are present.

It is advised that rooms in public buildings are locked with a two-stage lock during this cleansing process to prevent accidental human interruption. Luxibel provide a sticker and UVC label pack that can be stuck to doors and windows to advise the process is in place.

What automatic safety features are included with the units?

Damon: Luxibel have the most intelligent UVC lights on the market today, with 360 degree movement sensors, audible warnings and a red flashing LED to notify that the cleansing process is in operation. All units will shut down if the cycle is interrupted, and a full cycle is needed to ensure effectiveness after a shut-down. For safety reasons, that can only be triggered by a full restart.

Have there been any specific clinical trials to determine UVCs effectiveness against COVID-19, or are there any currently in progress?

Damon: A recent study at Boston University shows that the specific UVC tubes used by Luxibel for the Direct, Air, and Hybrid units are proven to kill Covid-19. You can find more information on that here:

https://tinyurl.com/y8awv6nz

www.luxibel.com/en/products/uvc-systems

www.ulagroup.com

Luxibel UVC Sterilisation Fixture range

CX Magazine – July 2020

LIGHTING | AUDIO | VIDEO | STAGING | INTEGRATION

Entertainment technology news and issues for Australia and New Zealand

– in print and free online www.cxnetwork.com.au

© VCS Creative Publishing

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.