Tech Talk

28 Sep 2022

The VL3000 Spot (Almost) 20 Years On

Subscribe to CX E-News

The once popular VL3000 spot is fast approaching its 20th birthday. Also known as the VL3K (VL stands for Vari-Lite), it was introduced to the global market in early 2003. It would take a few more years until it caught on and was a common sighting on gigs. They were very well known, so well know that they arguably became the industry standard in moving head spots. The VL3000 spot set the bar for a moving head spot in the industry during the mid to late 2000s and even into the early years of the 2010s.

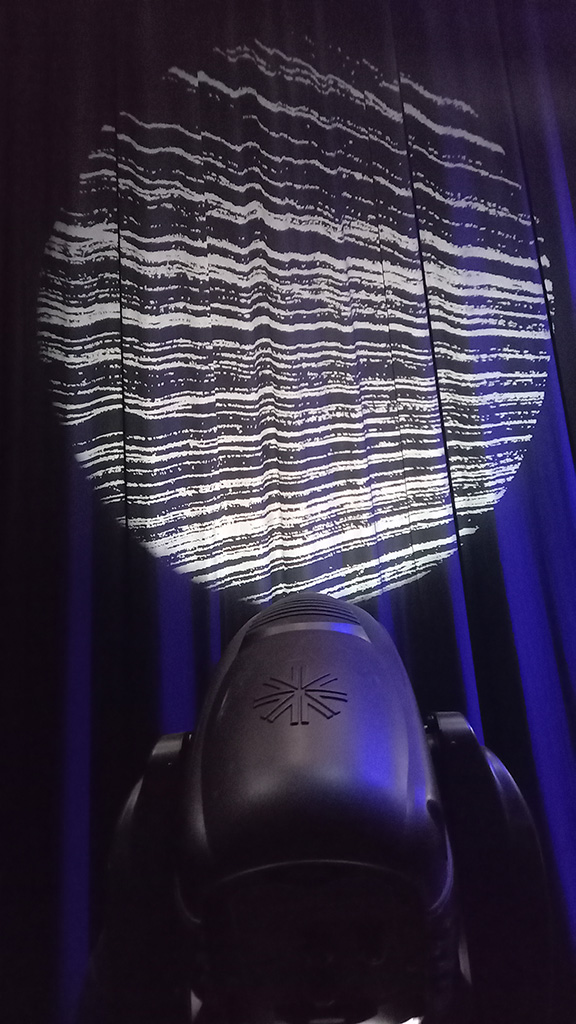

The VL3K offered operators and designers a solid all-round light with a good range of break up and beam gobos. Colour changes were crisp and fast. Rich, saturated colours could be achieved creating a whole new range of states and looks. Zoom range was respectable and the output was fantastic, even after frosts, colours and gobos were added. For what it was, it was a reasonably quiet light, provided it was well maintained. Pan and Tilt range was amongst the best on the market at the time and did its movements smoothly, quickly and accurately.

Unlike many moving lights of its era and beyond, the VL3K did not have the option to be patched with a standard and extended mode, instead opting for one mode only, which had a DMX footprint of 28 channels.

It stacked up well comparatively to the lights of its era. It did not have too many direct competitors. Arguably the closest competitor at the time was the Clay Paky Alpha Spot and later, the Viper Profile.

As the VL3000 got older, it came to be known as a reliable workhorse unit. With regular maintenance and cleaning they would continue to shine (pun intended). There was more than adequate cooling, both in regards to fans and empty space. Parts were robust, durable and easy to source when required. When there were faults, some of the more common issues included cracked head covers which led to light bleed, indexing issues where gobos and colour wheels could not find home, and ballast issues which would cause the light to intermittently lamp off, or not lamp on at all.

They were relatively easy lights to work on as well. Lamps were easy to access and replace, although getting the back cap back on afterwards could prove to be a little tricky at times. Changing gobos was as simple as opening up the head case with a Philips head screwdriver and popping the gobo out with a finger. Although they took the rather common E size gobo, it has a unique housing which made them quite distinctive. They were built as modular lights. Modules themselves were well laid quite simple to remove and replace, again, with nothing more than a Philips head screwdriver and remembering what plugs into where.

Cleaning and servicing the lights was also reasonably straight forward and simple to do. It was clear that thought was given to the job the technicians would have to do to be able to maintain the fixtures.

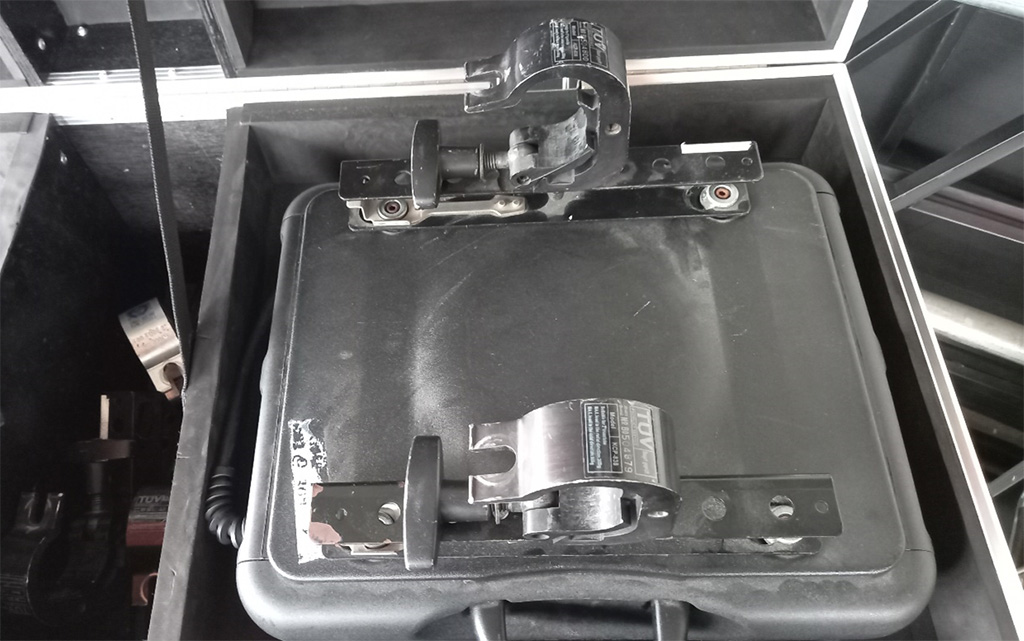

The design of the light allows for options for bracket orientation, very handy when it comes to hanging the light. The VL3K could be hung at any orientation. The brackets or rails also give many different option as to where to place clamps and what type of clamps to use. The safety chain was a custom length which allowed for minimum drop should it be required.

Nostalgia: Those who worked with the VL3000 may remember…

- A number of wheel based indexing issues (such as gobo and colour wheel positions) could be fixed with a black sharpie.

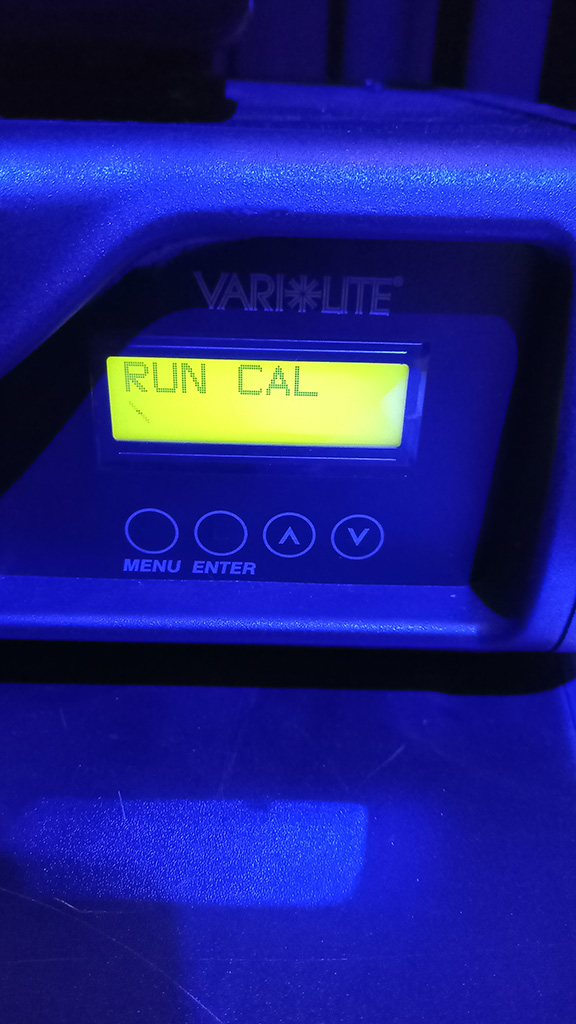

- On the onboard menu on the light, pressing the ‘Enter’ and the ‘Up’ buttons at the same time was a shortcut for lamping the fixture on.

- Conversely, pressing the ‘Enter’ and the ‘Down’ buttons at the same time would lamp the fixture off.

- The rather distinctive chattering sound heard on start-up, which was the shutters calibrating.

- The struggle of trying to lift one into the case and get it to sit right, especially the early cases

- The ‘Alpha Rays’ gobo

- Trying to figure out how to get the back cap on after a lamp change

Weighing in at 37kg, it was one of the heavier lights on the market at the time, despite featuring a lightweight, plastic head cover and numerous alloy components. It was definitely one of the more difficult lights to handle, not just because of the weight. No pan and tilt lock could make things a little unpredictable when lowering into a road case or flipping the light. The weight itself warranted a two-person lift/ flip more often than not.

Although materials have gotten lighter, and components have gotten smaller and more efficient, moving lights have gotten heavier. Some of the heavier moving lights around today include the PRG Best Boy at 50kg, Clay Paky Axcor 900 at 45kg, Ayrton Domino at 52kg and Martin Mac Ultra Performance at 44kg.

The VL3000’s lamp was a Phillips 1200W/S metal halide lamp. At 6000K it was classed as a cool white (or day white), similar to the colour temperature found in office buildings and shopping centres. They were readily available, easy to source and reasonably priced. Lamp life is listed as 750 hours.

When the lamps did explode or expire, they generally did not damage reflectors, flags, or cause issues with other components in the light, as is the case with some of the competitors.

The design and set up of the optical system gave the user the option of whether to utilise a flat field or a peaked field. That could be done using three lamp aligning screws located on the back cap of the light. A flat field is where there is no detectible hotspot in the beam of the light, and a peaked field is where the intensity of the beam is greater on the centre of the beam than the outer edges, therefore creating a ‘hotspot’ in the centre of the beam.

The VL3000’s colour system has a colour mixing mechanism and a fixed colour wheel. The colour mixing mechanism was made up with four graduated colour disks; Blue, Amber, Magenta and CTO. They provided full spectrum colour crossfades as well as pastel to saturated colour. The colour wheel had seven positions, one being open (white), the others being Congo Blue, Orange, Kelly Green, Dark Fuchsia (Purple), Magenta and Deep Red.

Although ground-breaking at the time it came was introduced to the market, much of the technology found in the VL3000 spot has been superseded by more modern technology such as LED light engines. These days, most of them sit unused, collecting dust, many with cracked covers, others in pieces. Although mostly redundant today, some can be found still in service in theatre shows and in venues around the country. Safe to say however, 10-15 years ago, almost any lighting operator would have been very happy to walk into a gig to find VL3Ks in their rig.

Vari-Lite Facts

- Vari-Lite is unofficially credited for inventing the first modern moving head fixture for entertainment purposes, the VL1

- It was rumoured that English band Genesis invested $1 million USD in research and development for the VL1. Fittingly, the first use of the VL1 would be on their tour with their album Abacab in late 1981.

- 860 VL1 fixtures were produced.

- Vari-Lite has won 3 Emmy awards for technical achievement; 1991: Outstanding Achievement in Engineering for the development of the 200 series; 1994: Outstanding Achievement in Engineering for the development of the VL5, and; 2000: Outstanding Achievement in Engineering for the development of the Virtuoso Console

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.